Risk Assessment of Plastic Pyrolysis Projects

Plastic pyrolysis projects offer a promising solution for managing plastic waste while producing valuable products like fuel oil, gas, and carbon black. However, like any large-scale industrial process, they come with a variety of risks. These risks span across technical, environmental, regulatory, and financial dimensions, and their careful evaluation is crucial to the success and sustainability of such projects. A comprehensive risk assessment allows stakeholders to address potential challenges proactively and develop effective mitigation strategies.

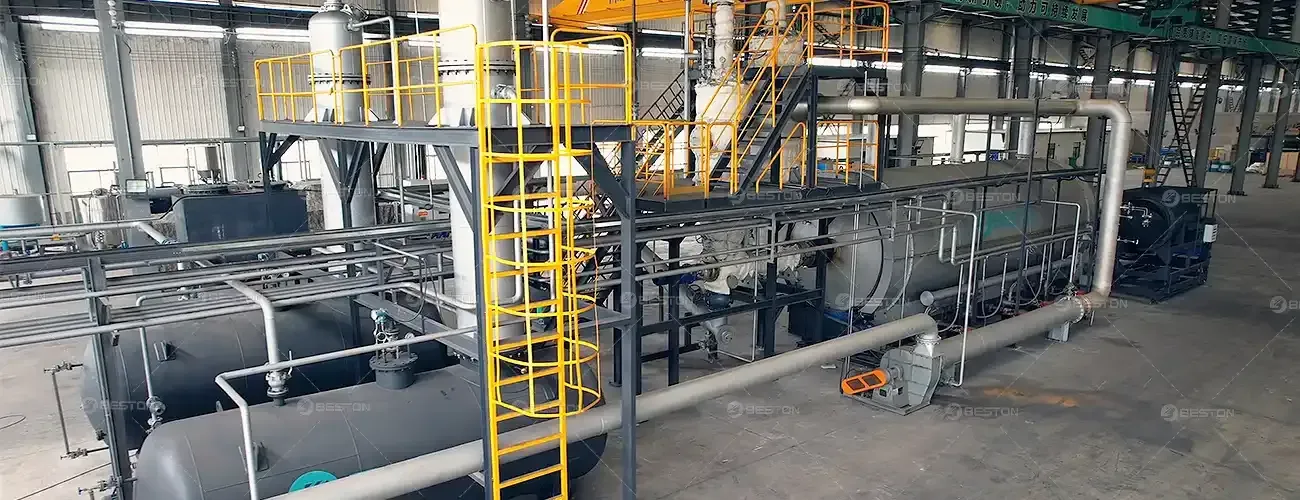

Technical and Operational Risks

Feedstock Variability and Quality

The type and quality of plastic feedstock can vary significantly depending on the source and collection method. Variations in plastic composition, contaminants, and moisture content can negatively impact the efficiency and consistency of the pyrolysis process. Feedstock quality issues may lead to operational instability, lower yields, or the production of suboptimal by-products.

To mitigate these risks, it is important to establish robust feedstock qualification procedures. This includes implementing sorting, cleaning, and drying steps before processing to ensure a consistent material input. Technological solutions such as automated sorting systems can help standardize the feedstock quality entering the plastic pyrolysis plant.

Process Control and Stability

Pyrolysis is a complex thermal decomposition process, and maintaining consistent temperature, pressure, and residence time is crucial for ensuring high-quality outputs. Variations in these parameters can lead to suboptimal product formation, equipment wear, or even safety hazards. For example, fluctuations in temperature can lead to incomplete pyrolysis, reducing the yield of valuable products like fuel oil or carbon black.

To manage these risks, it is vital to incorporate advanced control systems with real-time monitoring and automated adjustments. Using sensors, feedback loops, and predictive maintenance can help keep the pyrolysis process within optimal operating conditions, reducing downtime and enhancing product consistency.

Scale-Up Challenges

While pilot projects may perform well under controlled conditions, scaling up to a larger pyrolysis plant introduces several challenges. Scaling typically exposes issues related to heat distribution, material handling, and reactor design. Larger-scale operations may experience difficulties in maintaining uniform temperature profiles or achieving optimal gas recovery.

Risk mitigation in scaling can be achieved by performing thorough feasibility studies, engaging in small-scale pilot testing, and incorporating modular designs that allow for iterative scaling. This ensures that operational challenges are addressed before they become critical at full scale.

Environmental Risks

Emissions and Air Quality

One of the primary concerns with pyrolysis processes is the emission of volatile organic compounds (VOCs), particulate matter, and other pollutants during operation. The combustion of plastic materials can result in the release of toxic gases, such as dioxins and furans, which are harmful to both the environment and human health.

To address this, pyrolysis plant must integrate effective air pollution control systems such as scrubbers, filters, and gas treatment units. Continuous monitoring of air quality and emissions will ensure compliance with environmental standards and minimize the environmental impact of the operation.

Waste Management and By-products

Although pyrolysis transforms plastic waste into valuable products, it also generates by-products such as carbon black, char, and uncondensed gases. These by-products can pose environmental risks if not properly managed. For example, carbon black may contain impurities, and improperly disposed char can lead to soil contamination.

Risk management includes developing processes to either recycle or dispose of by-products in an environmentally safe manner. Additionally, research into utilizing carbon black in high-value applications (such as reinforcement in rubber products) can improve the economic feasibility of these by-products.

Feedstock Sourcing and Land Use

The sourcing of plastic waste for pyrolysis can lead to indirect environmental consequences. Improper sourcing or reliance on virgin plastic waste may undermine the environmental benefits of the process. Moreover, large-scale plastic waste collection operations could contribute to land-use changes, which may affect local ecosystems.

A sustainable feedstock sourcing strategy, including prioritizing post-consumer plastic waste, can mitigate these risks. Moreover, engaging in life-cycle assessments to quantify environmental benefits and ensuring that plastic waste is sourced ethically are critical steps.

Regulatory and Legal Risks

Regulatory Compliance and Permits

Plastic pyrolysis plants must adhere to a wide range of environmental and safety regulations. These may include local, national, or international standards regarding air quality, waste management, emissions, and safety protocols. Non-compliance with these regulations can lead to fines, shutdowns, or even project cancellation.

Regulatory risks can be minimized by maintaining close relationships with regulatory bodies and engaging in ongoing compliance monitoring. This includes obtaining all necessary permits and adhering to established safety standards during construction and operation.

Changing Regulations and Standards

The regulatory landscape for waste management and carbon emissions is continuously evolving. Governments worldwide are increasingly tightening regulations on waste processing, emissions, and resource recovery. These changes could impact the viability of a plastic pyrolysis plant, particularly if new regulations impose stricter emission limits or require additional monitoring systems.

Proactively monitoring changes in environmental regulations and ensuring the flexibility of project designs to meet future requirements can help mitigate this risk. Additionally, incorporating adaptability into the project’s operational framework ensures that the plant can quickly comply with new regulations as they arise.

Liability and Long-Term Monitoring

The long-term environmental impacts of a plastic pyrolysis plant are often uncertain. If, over time, the plant’s operations cause harm to the environment, there could be legal liability for the company. This includes risks related to emissions, waste handling, and the potential long-term effects of the by-products.

To reduce this risk, implementing a long-term monitoring program, coupled with insurance and indemnity clauses, will ensure that potential liabilities are covered. Long-term environmental stewardship plans are essential for mitigating any unforeseen risks that may arise after the plant has been operational for years.

Financial and Economic Risks

Capital Investment and Funding

The initial capital investment required to establish a plastic pyrolysis plant is substantial. This includes the cost of procuring the pyrolysis plant, installation, infrastructure, and ongoing operating expenses. Securing adequate funding to cover these costs can be a challenge, especially given the long payback periods of pyrolysis projects.

Securing diverse funding sources, including government grants, private investors, or partnerships with environmental organizations, can help mitigate the financial risk. Additionally, conducting thorough financial modeling and project forecasting is necessary to ensure that the plant’s financial returns justify the initial investment.

Market Volatility and Product Pricing

The market for products derived from plastic pyrolysis, such as fuel oil, carbon black, and gas, can be volatile. Changes in commodity prices, shifts in demand, or the emergence of competing technologies could impact the plant’s profitability.

Diversifying the plant’s product offerings and developing strategic partnerships with key industries can help stabilize revenue streams. Regular market analysis and adapting to demand shifts are essential to navigate this financial risk effectively.

Economic and Market Risk

Economic downturns, geopolitical instability, or shifts in public policy can all impact the viability of a plastic pyrolysis plant. These external factors can influence feedstock availability, market demand, or regulatory frameworks, creating uncertainty in the long-term profitability of the project.

Diversifying supply chains, exploring alternative feedstock options, and maintaining flexibility in operations can mitigate some of these risks. Additionally, staying aligned with global sustainability goals and trends can enhance the project’s long-term economic feasibility.