New Paragraph

Beston Group

Web: https://bestonmachinery.com/.

Email: sales@bestonmachinery.com

Egg Tray Making Machine

Web: https://bestoneggtraymachine.com/.

Email: sales@bestoneggtraymachine.com.

New Paragraph

https://bestonmachinery.com/charcoal-making-machine/

https://bestonmachinery.com/biochar-production-equipment/

https://bestonmachinery.com/charcoal-making-machine/sawdust/

https://bestonmachinery.com/charcoal-making-machine/palm-kernel-shell/

https://bestonmachinery.com/biochar-production-equipment/reactor/

https://bestonmachinery.com/charcoal-making-machine/videos/

https://bestonmachinery.com/charcoal-making-machine/faqs/

https://bestonmachinery.com/biochar-production-equipment/reactor/

https://bestonmachinery.com/biomass-pyrolysis-plant/

https://bestonmachinery.com/charcoal-making-machine/components/

https://bestonmachinery.com/charcoal-making-machine/price/

https://bestonmachinery.com/charcoal-production-machine/

https://bestonmachinery.com/charcoal-making-machine/coconut-shell/

https://bestonmachinery.com/charcoal-making-machine/rice-hull/

https://bestonmachinery.com/wood-pyrolysis-plant/

https://bestonmachinery.com/charcoal-making-machine/jute-stick/

https://bestonmachinery.com/charcoal-making-machine/bamboo/

https://bestonmachinery.com/charcoal-making-machine/sugarcane-bagasse/

https://bestonmachinery.com/coconut-shell-charcoal-making-machine-price/

https://bestonmachinery.com/shisha-charcoal-making-machine/

https://bestonmachinery.com/charcoal-making-machine/wood/

https://bestonmachinery.com/carbonization-machine/

https://bestonmachinery.com/charcoal-manufacturing-machine/

https://bestonmachinery.com/biochar-production-equipment/mobile/

https://bestonmachinery.com/products/

https://bestonmachinery.com/straw-charcoal-machine/

https://bestonmachinery.com/solutions/

https://bestonmachinery.com/biochar-machine-for-sale/

https://bestonmachinery.com/biomass-carbonization-machine/

https://bestonmachinery.com/carbonization-furnace/

https://bestonmachinery.com/carbon-sequestration-and-emission-reduction-solution/

https://bestonmachinery.com/soil-remediation-and-improvement-solution/

https://bestonmachinery.com/biomass-charcoal-as-fuel-alternative-for-industries/

https://bestonmachinery.com/pulp-moulding-products/

https://bestonmachinery.com/charcoal-making-machine-for-sale/

https://bestonmachinery.com/bbq-charcoal-making-machine/

https://bestonmachinery.com/charcoal-making-machine/continuous/

https://bestonmachinery.com/biochar-pyrolysis-equipment/

https://bestonmachinery.com/biomass-charcoal-making-machine/

https://bestonmachinery.com/sewage-sludge-carbonization-plant/

https://bestonmachinery.com/charcoal-making-machine/small/

https://bestonmachinery.com/charcoal-making-machine-in-cameroon/

https://bestonmachinery.com/charcoal-making-machine-in-cote-divoire/

https://bestonmachinery.com/charcoal-making-machine-in-morocco/

https://bestonmachinery.com/charcoal-making-machine-in-kenya/

https://bestonmachinery.com/charcoal-making-machine-in-south-korea/

https://bestonmachinery.com/charcoal-making-machine-in-thailand/

https://bestonmachinery.com/charcoal-making-machine-in-ghana/

https://bestonmachinery.com/charcoal-making-machine-in-the-philippines/

https://bestonmachinery.com/charcoal-making-machine-in-sri-lanka/

https://bestonmachinery.com/charcoal-making-machine-in-turkey/

https://bestonmachinery.com/charcoal-making-machine-in-the-united-states/

https://bestonmachinery.com/pyrolysis-plant/

https://bestonmachinery.com/pyrolysis-plant/continuous/

https://bestonmachinery.com/pyrolysis-plant/reactor/

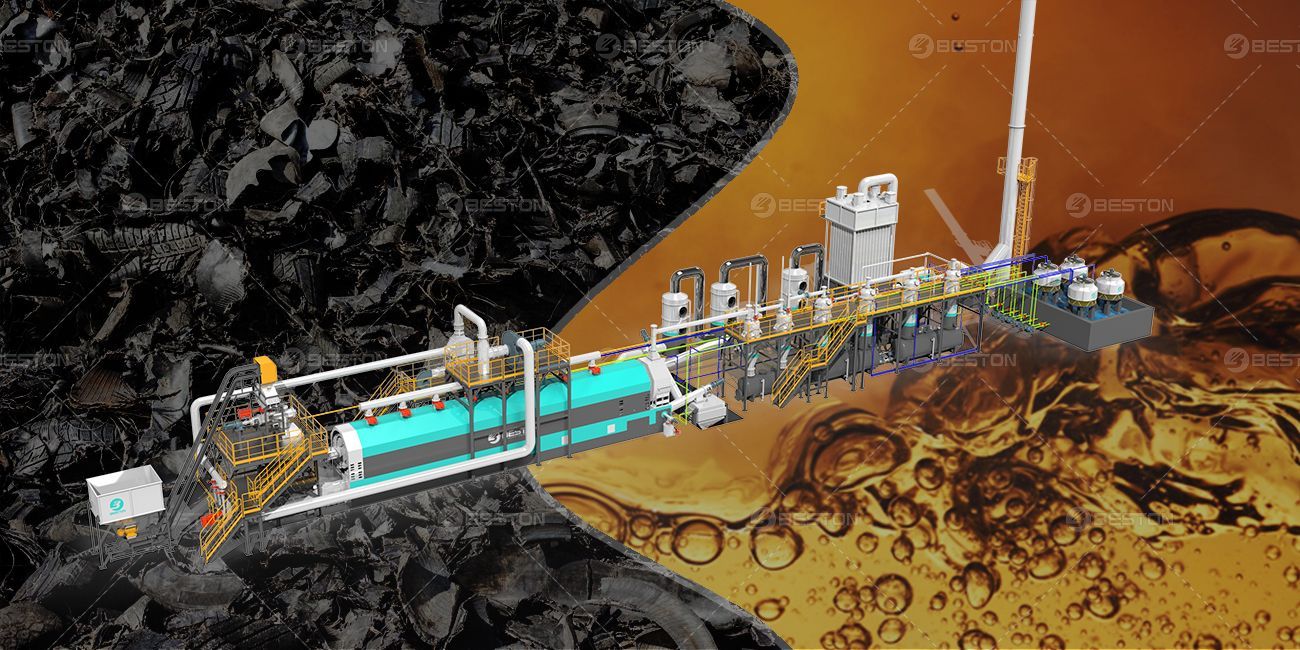

https://bestonmachinery.com/tyre-pyrolysis-plant/

https://bestonmachinery.com/plastic-to-fuel-machine/

https://bestonmachinery.com/pyrolysis-plant/faqs/

https://bestonmachinery.com/pyrolysis-plant/mini-skid-mounted/

https://bestonmachinery.com/pyrolysis-plant/manufacturer/

https://bestonmachinery.com/tyre-pyrolysis-plant/project-report/

https://bestonmachinery.com/pyrolysis-plant/cost/

https://bestonmachinery.com/pyrolysis-plant/videos/

https://bestonmachinery.com/oil-sludge-pyrolysis-plant/

https://bestonmachinery.com/pyrolysis-plant/mobile/

https://bestonmachinery.com/tyre-to-oil-plant/

https://bestonmachinery.com/tyre-to-oil-plant/

https://bestonmachinery.com/rubber-pyrolysis-plant/

https://bestonmachinery.com/pyrolysis-plant/technology/

https://bestonmachinery.com/pyrolysis-plant/process/

https://bestonmachinery.com/pyrolysis-plant/small/

https://bestonmachinery.com/tyre-to-fuel-recycling-plant/

https://bestonmachinery.com/thermal-desorption-unit/

https://bestonmachinery.com/pyrolysis-plant/components/

https://bestonmachinery.com/pyrolysis-plant/semi-continuous/

https://bestonmachinery.com/pyrolysis-system/

https://bestonmachinery.com/plastic-pyrolysis-plant/

https://bestonmachinery.com/pyrolysis-plant-in-morocco/

https://bestonmachinery.com/pyrolysis-machine-in-egypt/ https://bestonmachinery.com/pyrolysis-plant-in-zimbabwe/ https://bestonmachinery.com/pyrolysis-plant-in-australia/ https://bestonmachinery.com/pyrolysis-plant/uk/ https://bestonmachinery.com/pyrolysis-plant/the-philippines/

https://bestonmachinery.com/pyrolysis-plant/nigeria/

https://bestonmachinery.com/pyrolysis-plant/malaysia/ https://bestonmachinery.com/pyrolysis-plant-in-canada/ https://bestonmachinery.com/pyrolysis-plant-in-china/ https://bestonmachinery.com/tyre-pyrolysis-plant-in-uae/

https://bestonmachinery.com/pyrolysis-plant-in-morocco/

https://bestonmachinery.com/pyrolysis-machine-in-egypt/

https://bestonmachinery.com/pyrolysis-plant-in-zimbabwe/

https://bestonmachinery.com/pyrolysis-plant-in-australia/

https://bestonmachinery.com/pyrolysis-plant/uk/

https://bestonmachinery.com/pyrolysis-plant/the-philippines/

https://bestonmachinery.com/pyrolysis-plant/nigeria/

https://bestonmachinery.com/pyrolysis-plant/malaysia/

https://bestonmachinery.com/pyrolysis-plant-in-canada/

https://bestonmachinery.com/pyrolysis-plant-in-china/

https://bestonmachinery.com/tyre-pyrolysis-plant-in-uae/

https://bestonmachinery.com/pyrolysis-plant-in-pakistan/

https://bestonmachinery.com/pyrolysis-plant-in-botswana/

https://bestonmachinery.com/pyrolysis-plant-in-indonesia/

https://bestonmachinery.com/pyrolysis-oil-as-fuel-alternative-for-industries/

https://bestonmachinery.com/oil-contaminated-soil-remediation-solution/

https://bestonmachinery.com/tyre-shredder/

https://bestonmachinery.com/industrial-packaging-machine/

https://bestonmachinery.com/egg-tray-making-machine-in-saudi-arabia/

https://bestonmachinery.com/egg-tray-making-machine-in-morocco/

https://bestonmachinery.com/egg-tray-making-machine-in-russia/

https://bestonmachinery.com/egg-tray-making-machine/philippines/

https://bestonmachinery.com/egg-tray-making-machine/china/

https://bestonmachinery.com/egg-tray-making-machine/price-in-india/

https://bestonmachinery.com/egg-tray-making-machine/turkey/

https://bestonmachinery.com/egg-tray-making-machine/nigeria/

https://bestonmachinery.com/egg-tray-making-machine/price/

https://bestonmachinery.com/apple-tray-making-machine/

https://bestonmachinery.com/egg-tray-making-machine/videos/

https://bestonmachinery.com/egg-tray-making-machine/dryer/

https://bestonmachinery.com/turnkey-project/

https://bestonmachinery.com/egg-tray-making-machine/project-report/

https://bestonmachinery.com/egg-tray-packing-machine/

https://bestonmachinery.com/paper-tray-making-machine/

https://bestonmachinery.com/egg-tray-making-machine/manual/

https://bestonmachinery.com/pulp-molding-machine/manufacturers/

https://bestonmachinery.com/egg-crate-making-machine/

https://bestonmachinery.com/egg-tray-manufacturing-machine/

https://bestonmachinery.com/egg-tray-making-machine/for-sale/

https://bestonmachinery.com/egg-carton-machine/

https://bestonmachinery.com/egg-tray-making-machine-in-egypt/

https://bestonmachinery.com/egg-tray-making-machine-in-iraq/

https://bestonmachinery.com/egg-tray-making-machine/india/

https://bestonmachinery.com/egg-tray-making-machine/pakistan/

https://bestonmachinery.com/egg-tray-making-machine/philippines/

https://bestonmachinery.com/egg-tray-making-machine/china/

https://bestonmachinery.com/egg-tray-making-machine/price-in-india/

https://bestonmachinery.com/egg-tray-making-machine/turkey/

https://bestonmachinery.com/egg-tray-making-machine/nigeria/

https://bestonmachinery.com/egg-box-machine/

https://bestonmachinery.com/egg-tray-making-machine/800-1000/

https://bestonmachinery.com/egg-tray-making-machine/1200-1500/

https://bestonmachinery.com/egg-tray-making-machine/2000pcs/

https://bestonmachinery.com/egg-tray-making-machine/2200-2500/

https://bestonmachinery.com/egg-tray-making-machine/3500-4500/

https://bestonmachinery.com/egg-tray-making-machine/5000-5500/