Technical Barriers in Rice Husk Biochar Production

Producing biochar from rice husk presents a unique combination of technical and operational challenges. Despite its abundance and carbon-rich composition, rice husk is a difficult biomass to process efficiently. The intricacies lie not only in its physical and chemical characteristics but also in how these traits interact with the design and control of a pyrolysis plant. Addressing these barriers is essential for ensuring stable output, high yield, and consistent biochar quality suitable for carbon removal or industrial applications.

Complex Feedstock Characteristics

Rice husk exhibits an atypical structure compared to other agricultural residues. It contains a high silica fraction, sometimes exceeding 15–20% by weight, and a low bulk density. The combination complicates thermal decomposition. The silica forms a rigid outer shell, impeding heat transfer during pyrolysis and reducing rice hull carbonizer efficiency. This results in nonuniform heating zones and incomplete carbonization when using conventional batch systems.

The low bulk density further reduces reactor loading capacity, demanding higher feed volumes for equivalent throughput. Conveying and feeding rice husk into a reactor also require mechanical adaptations—standard auger systems tend to clog due to the lightweight and flaky morphology of the material. Continuous feeding mechanisms, therefore, must incorporate air-assisted systems or specially designed compression devices to stabilize feed flow.

Temperature Control and Reaction Uniformity

Effective temperature management is crucial in rice husk pyrolysis. The reaction window typically ranges from 400°C to 650°C, yet maintaining uniform temperature distribution within the reactor is difficult due to uneven packing density and thermal resistance from silica layers. Overheating can trigger localized ash fusion, damaging reactor linings and lowering biochar surface area. Conversely, insufficient temperature leads to high volatile content and under-carbonized residues.

Advanced biomass pyrolysis plant configurations use multi-zone temperature control, internal recirculation of hot gas, and real-time monitoring of bed temperature to maintain homogeneity. Even so, achieving equilibrium between energy input, residence time, and yield remains one of the most persistent engineering difficulties.

Energy Consumption and Process Efficiency

The energy intensity of rice husk carbonization is notably higher than that of other feedstocks. The inherent high ash content reduces the calorific value of the feed, meaning external heat supplementation is often required. This increases operational costs and impacts lifecycle emission balance, especially for projects targeting certified carbon removal outcomes.

Energy recovery from syngas and volatile components can offset part of the consumption, but such systems must be tightly integrated. Poor gas sealing or inefficient combustion of off-gas can lead to substantial heat loss. Continuous pyrolysis configurations tend to outperform batch systems in this regard, providing better energy utilization and consistent heat profiles through closed-loop control.

Biochar Quality and Market Compatibility

The quality of rice husk biochar varies widely based on pyrolysis temperature, residence time, and feed conditioning. High silica content leads to lower fixed carbon ratios and reduced cation exchange capacity, affecting its suitability for soil enhancement or industrial applications. For carbon removal certification, the produced biochar must meet specific thresholds in carbon stability and impurity concentration—criteria that rice husk often struggles to satisfy without process optimization.

Further, the fine particle size and low bulk density of the resulting biochar complicate packaging, transport, and downstream use. Pelletization or blending with denser materials is sometimes necessary, adding logistical costs.

Equipment Durability and Maintenance Challenges

Rice husk’s abrasive nature accelerates wear on feeding systems, reactor walls, and discharge screws. Silica particulates act as micro-abrasives, shortening the operational lifespan of metal components. Thermal descaling and slag removal are also more frequent compared to wood or nutshell-based systems. As a result, pyrolysis plants handling rice husk require high-grade refractory materials, abrasion-resistant alloys, and periodic maintenance schedules to sustain performance.

Preventive maintenance protocols, combined with automated monitoring of vibration, pressure, and feed rate, can reduce downtime. However, the initial capital investment for such durability enhancements remains substantial.

Pathways Toward Optimization

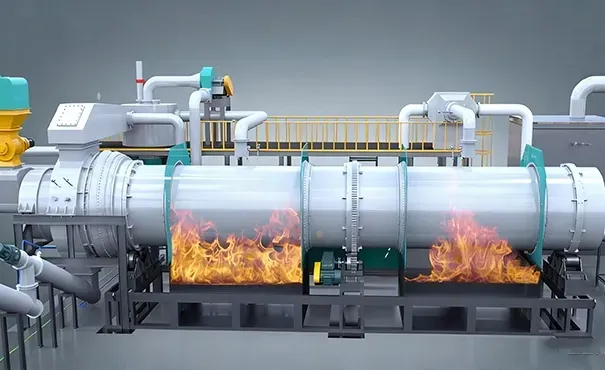

Despite these hurdles, advances in reactor engineering are gradually mitigating the constraints. Fluidized-bed and rotary kiln pyrolysis plants offer improved mixing and heat distribution, lowering the risk of localized overheating. Pre-treatment processes such as densification or mild torrefaction improve feed uniformity and increase throughput efficiency.

Process integration—utilizing waste heat for drying and leveraging excess syngas for power generation—further enhances economic sustainability. These refinements collectively push rice husk biochar production closer to commercial viability.

Ultimately, the key to overcoming the inherent difficulties of rice husk carbonization lies in precision engineering and adaptive process control. Only by aligning feedstock behavior with advanced reactor design can a pyrolysis plant achieve consistent, high-quality biochar output while maintaining energy efficiency and long-term operational stability.