Advantages of Producing Charcoal from Coconut Shell

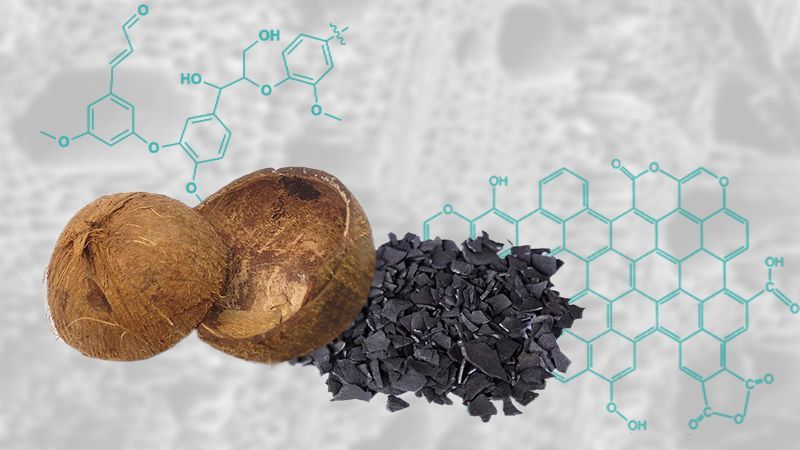

Coconut shells, often treated as agricultural residue, possess exceptional characteristics that make them one of the most efficient and sustainable feedstocks for charcoal manufacturing. Their dense lignocellulosic structure, low ash composition, and renewable origin collectively position coconut shell charcoal as a high-value bio-based material suitable for both industrial and domestic applications. Modern pyrolysis plant technology enables precise conversion of this biomass into clean, energy-rich charcoal with minimal environmental footprint.

Structural Superiority and High Carbon Yield

Coconut shell is naturally compact and rich in lignin, a polymer that enhances carbon density during thermal decomposition. When subjected to pyrolysis under controlled conditions, the shell produces a charcoal with fixed carbon content exceeding 80%, significantly higher than that of most hardwood-derived products. The low volatile matter ensures stable combustion of charcoal machine, generating high calorific value while minimizing smoke and residue.

The high hardness of coconut shell also results in a uniform pore structure within the charcoal matrix. This micro-porosity not only improves ignition and heat distribution but also makes the material highly desirable for activated carbon production. Industries engaged in air purification, gold recovery, and solvent filtration prefer coconut shell-based carbon due to its durability and adsorption performance.

Efficient Conversion through Pyrolysis Technology

The transformation of coconut shell into charcoal is achieved through a coconut shell charcoal making machine operating in an oxygen-limited environment. The process typically involves heating the shells to 450–600°C, where volatile compounds decompose and escape as gas, leaving behind stable carbon. Advanced systems feature continuous feeding, automatic temperature control, and gas recovery units to enhance thermal efficiency and reduce emissions.

The non-condensable gases produced during pyrolysis can be redirected as a supplementary fuel source for the reactor, minimizing external energy input. The condensable fraction, consisting of bio-oil and tar, can be further refined into fuel or chemical intermediates, creating additional value streams. Thus, the overall energy balance of a modern pyrolysis system is self-sustaining and economically advantageous.

Environmental and Economic Benefits

Producing charcoal from coconut shell represents a circular use of agricultural waste that would otherwise contribute to landfill accumulation or open burning emissions. The carbonization process, when properly managed, yields biochar that sequesters carbon for long durations, contributing to carbon offset and climate mitigation goals. Unlike traditional wood charcoal, this pathway does not involve deforestation, thereby reducing ecological stress on forest resources.

Economically, the availability of abundant coconut residues in tropical regions ensures a consistent and low-cost feedstock supply. This accessibility significantly reduces raw material expenses, which constitute a major share of operational costs in charcoal production. Additionally, by-products such as bio-oil and syngas can be monetized, improving project profitability and resilience against feedstock price fluctuations.

The clean-burning nature of coconut shell charcoal also enhances its marketability in the barbecue and hospitality industries, where consumers prioritize odorless, smokeless, and long-lasting fuels. Its uniform size and low ash content translate into operational convenience and higher combustion efficiency compared to softwood or coal-based alternatives.

Applications in Sustainable Industry

Beyond fuel use, coconut shell charcoal serves as an input for a range of industrial applications. Its stable carbon matrix is ideal for metallurgical reduction, soil amendment, and water filtration systems. When upgraded to activated carbon, it exhibits superior adsorption capacity due to its high micropore volume and low mineral impurities.

In agricultural contexts, integrating coconut shell biochar into soil improves nutrient retention and microbial balance, facilitating long-term fertility enhancement. When produced via a certified pyrolysis plant, such biochar may also qualify for carbon credit generation under recognized carbon removal frameworks, adding environmental and financial value to the process.

Toward a Renewable Carbon Economy

Coconut shell charcoal production represents a convergence of sustainability, resource efficiency, and economic viability. It utilizes an abundant biomass residue, transforms it through clean pyrolytic conversion, and delivers a versatile carbon product that supports multiple industries.

As the global shift toward low-carbon materials accelerates, leveraging coconut shell as a renewable carbon source provides both environmental stewardship and commercial advantage. The integration of advanced pyrolysis systems enables scalable and consistent production, reinforcing the role of coconut shell charcoal as a cornerstone in the emerging circular bioeconomy.