Profitability Analysis of a Coconut Shell Charcoal Project

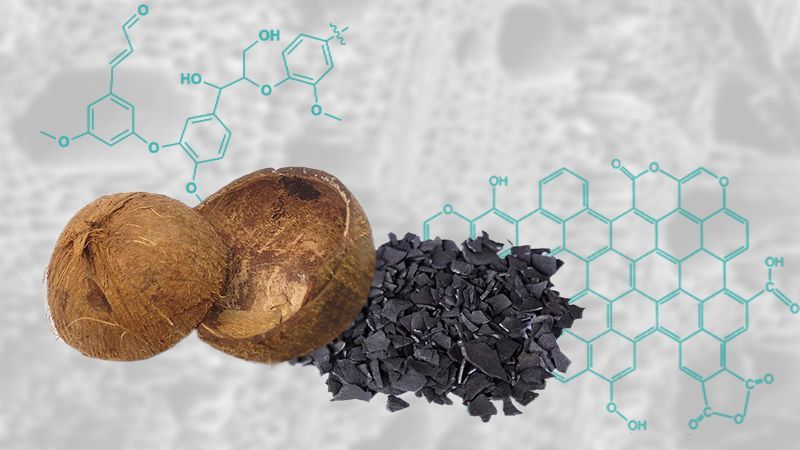

Coconut shell charcoal production has emerged as a profitable venture due to the growing demand for eco-friendly energy solutions and sustainable materials. Utilizing waste coconut shells to produce high-quality charcoal has become an attractive business, particularly in regions with abundant coconut production. The ability of the coconut shell charcoal machine to convert waste into valuable charcoal, bio-oil, and syngas contributes significantly to the overall economic feasibility of such projects. This analysis delves into the profitability of investing in a coconut shell charcoal project, taking into account factors such as raw material costs, processing expenses, market demand, and revenue streams.

Raw Material Availability and Cost

One of the fundamental advantages of coconut shell charcoal production is the availability of raw materials. Coconut shells are a by-product of coconut processing industries, making them abundant in regions where coconut farming is prevalent. Countries such as India, Indonesia, the Philippines, and Thailand are among the leading producers of coconuts, which ensures a steady supply of shells for charcoal production.

The cost of coconut shells is generally low, as they are considered agricultural waste. Farmers and processing plants often dispose of these shells at minimal prices, and in some cases, they are given away for free. This low-cost raw material contributes to reducing the overall production costs, which significantly enhances the profitability of the project. Additionally, using waste materials aligns with sustainability goals, which can further improve the marketability of the final product.

Capital Investment and Equipment

A major consideration in the profitability analysis is the capital investment required for purchasing and installing a coconut shell https://bestonmachinery.com/charcoal-making-machine/. The cost of the machine can vary depending on its capacity, automation level, and technological features. A small-scale plant might require a lower initial investment but could be limited in terms of production capacity. In contrast, a large-scale, fully automated plant can process more raw material efficiently but requires a higher upfront investment.

The type of technology employed in the machine also impacts the overall profitability. Modern coconut shell charcoal machines are designed with advanced pyrolysis technology that maximizes the conversion of coconut shells into charcoal, bio-oil, and syngas. These machines are equipped with energy recovery systems that minimize energy consumption, further improving the cost-effectiveness of the operation. While the initial capital outlay may be substantial, the long-term benefits of reduced energy consumption and higher yields justify the investment.

Operating Costs

Operating costs for a coconut shell charcoal project include expenses for labor, energy, maintenance, and transportation. Labor costs vary depending on the region, but operating a coconut shell charcoal machine typically requires a small workforce. Modern machines are highly automated, reducing the need for manual labor and minimizing human error. Automation also speeds up the production process, increasing overall output and reducing labor costs.

Energy consumption is another critical factor in determining profitability. The pyrolysis process, which converts coconut shells into charcoal, requires a controlled, high-temperature environment. However, many coconut shell charcoal machines are equipped with energy-efficient systems that utilize syngas, a by-product of the pyrolysis process, to power parts of the machine. This reduces reliance on external energy sources and helps lower operational expenses.

Maintenance costs, though essential, are generally low for modern machines, which are designed for durability and long-term operation. Routine maintenance, including cleaning, lubrication, and part replacements, ensures that the machine functions efficiently over time. Transportation costs, on the other hand, depend on the proximity of the production site to both the raw material source and the end market.

Product Yield and Quality

The profitability of a coconut shell charcoal project is closely tied to the product yield and the quality of the final product. A well-designed coconut shell charcoal machine can achieve high conversion rates, turning a significant portion of the raw coconut shells into usable charcoal. The quality of the charcoal produced depends on factors such as temperature control, feedstock moisture content, and pyrolysis duration. Higher quality charcoal fetches better market prices, especially in niche markets such as activated carbon production or industrial energy applications.

By-products such as bio-oil and syngas can also contribute to profitability. Bio-oil can be sold as a fuel or raw material for chemical industries, while syngas can be used to generate heat or electricity for the plant, reducing operational costs. These by-products not only create additional revenue streams but also improve the overall energy efficiency of the plant.

Market Demand and Pricing

Coconut shell charcoal has a wide range of applications, making it a versatile and highly marketable product. It is used in household cooking, industrial heating, metallurgical processes, and the production of activated carbon. Activated carbon, in particular, has high demand due to its use in water purification, air filtration, and gas adsorption processes. The increasing awareness of environmental issues and the need for sustainable energy sources have further boosted the demand for coconut shell charcoal.

Market prices for coconut shell charcoal vary depending on the region, product quality, and end-use application. In developing markets, where charcoal is primarily used for cooking, prices may be lower. However, in industrialized nations, where charcoal is used in high-value applications such as activated carbon production, the prices can be significantly higher. Understanding the target market and positioning the product accordingly is crucial for maximizing profitability.

Environmental and Social Benefits

While the focus of this analysis is on profitability, it is worth noting the environmental and social benefits of coconut shell charcoal machine. The project contributes to waste reduction by utilizing coconut shells, which would otherwise be discarded or burned, releasing harmful emissions into the atmosphere. Charcoal production through pyrolysis is a cleaner alternative compared to traditional charcoal production methods, as it reduces emissions and captures valuable by-products.

Furthermore, coconut shell charcoal projects create job opportunities in rural areas, contributing to local economic development. By providing a sustainable livelihood for coconut farmers and workers, these projects can improve the socio-economic conditions in coconut-producing regions.

Break-Even Analysis and ROI

A thorough profitability analysis should include a break-even calculation to determine how long it will take to recoup the initial investment. The break-even point is influenced by factors such as the cost of raw materials, production capacity, operating expenses, and market demand. A typical coconut shell charcoal machine can start generating profits within 1 to 3 years, depending on the scale of the project and the market conditions.

Return on investment (ROI) is another key indicator of profitability. A well-optimized coconut shell charcoal project can achieve an ROI of 15% to 30%, depending on the efficiency of the plant and the market price of the final products. Factors such as economies of scale, operational efficiency, and the ability to sell by-products can further enhance ROI.

Conclusion

The profitability of a coconut shell charcoal project depends on several factors, including raw material costs, capital investment, operating expenses, and market demand. With the right technology, such as a modern coconut shell charcoal machine, this venture can be highly profitable, particularly in regions with abundant coconut production. The ability to produce high-quality charcoal and valuable by-products such as bio-oil and syngas adds to the economic viability of the project. Moreover, the environmental and social benefits make coconut shell charcoal production an attractive option for sustainable development. With careful planning and optimization, a coconut shell charcoal project can provide substantial returns for investors while contributing positively to the environment and local communities.