Influence of Coconut Shell Properties on Charcoal Production

- By Beston Charcoal

- •

- 15 Jan, 2025

- •

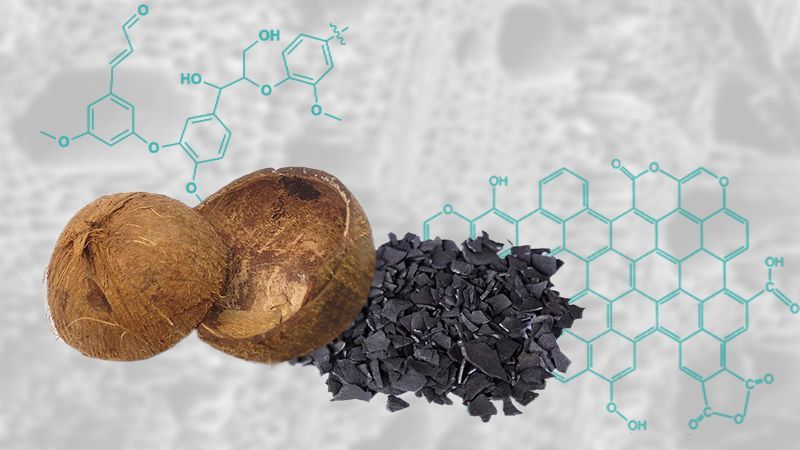

Coconut shells are a valuable biomass feedstock for charcoal production, due to their high carbon content and dense structure. The properties of coconut shells significantly affect the quality and efficiency of charcoal production. Understanding how these inherent properties interact with the charcoal production process can optimize the output, reduce waste, and ensure the production of high-quality charcoal.

Physical Characteristics of Coconut Shells

Coconut shells possess a rigid, durable structure that makes them ideal for conversion into charcoal. The material is dense, which allows for better heat retention during the pyrolysis process. This density is an essential factor as it directly influences the efficiency of thermal decomposition. When processed in a charcoal making machine, the high density of coconut shells leads to a slower and more controlled conversion, ensuring that the final charcoal product is uniform and of higher quality.

Another important physical property is the size and shape of the coconut shells. Larger, well-formed shells typically yield higher quantities of charcoal compared to smaller or fragmented shells. This is because smaller pieces tend to produce inconsistent results due to uneven heating and burning. Thus, the physical integrity of the shells plays a significant role in determining the yield and consistency of the charcoal.

Impact of Shell Preparation on Charcoal Quality

Before being processed in a coconut charcoal making machine, coconut shells are often cleaned, crushed, and dried. The preparation steps significantly impact the final product's quality. Crushing the shells into smaller pieces enhances the surface area, allowing for more efficient heat penetration during pyrolysis. However, it is essential to balance the size of the pieces to avoid over-crushing, which can lead to inconsistent heating and char production.

Drying the shells before pyrolysis is also a critical step. Excess moisture can dilute the pyrolysis process, requiring more energy to break down the biomass and reducing the overall efficiency. Therefore, coconut shells with lower moisture content prior to processing are ideal, as they reduce energy consumption and lead to a higher yield of charcoal.

Chemical Composition of Coconut Shells

The chemical makeup of coconut shells contributes heavily to the efficiency and quality of charcoal production. The shells are rich in lignocellulosic materials, particularly cellulose, hemicellulose, and lignin, which are key to the pyrolysis process. During pyrolysis, these organic compounds undergo thermal decomposition, breaking down into volatile gases and leaving behind carbon-rich solid char. The higher the lignocellulose content, the more likely the shells will produce a high carbon yield during the pyrolysis process.

Coconut shells typically contain lower amounts of impurities such as ash and sulfur, compared to other biomass feedstocks. This characteristic is crucial because lower impurities result in cleaner charcoal, reducing the amount of contaminants in the final product. Ash content, in particular, affects the burning efficiency and quality of charcoal, as high ash levels can reduce heat output and produce more residual waste. The minimal ash content in coconut shells is therefore advantageous in producing higher-quality charcoal with more efficient burning properties.

The relatively low moisture content of coconut shells is another factor that affects charcoal production. Shells with lower moisture content require less energy to heat and undergo pyrolysis. This not only improves the overall efficiency of the process but also ensures that the charcoal produced has a lower moisture percentage, which is desirable for fuel and industrial applications.

Thermal Decomposition and Charcoal Yield

The thermal decomposition of coconut shells is influenced by both their physical and chemical properties. During pyrolysis, the shells are subjected to high temperatures, typically between 400°C and 800°C, in the absence of oxygen. The volatile compounds present in the shells, including gases like carbon dioxide, carbon monoxide, methane, and water vapor, are released during this process, leaving behind the carbon-rich charcoal. The rate of decomposition, the temperature profile, and the duration of the pyrolysis process all interact with the properties of the coconut shells to determine the overall yield and quality of the charcoal.

The dense structure of the coconut shells means that they require a longer pyrolysis period to break down completely. While this results in a slightly lower yield per unit of time compared to lighter feedstocks, it produces a high-quality product with enhanced burning characteristics. The slow pyrolysis process allows for better retention of the carbon content, ensuring that the resulting charcoal has higher energy content, longer burn time, and a minimal amount of ash residue.

Additionally, the chemical composition of the coconut shells dictates the distribution of volatile compounds and the carbon content in the final product. High lignin content typically results in a charcoal with better hardness and durability, making it suitable for industrial applications like metal smelting or as a high-efficiency fuel for cooking and heating.