What You Need To Understand The Rotary Paper Egg Tray Making Machine

Rotary Paper Egg Tray Making Machine Manufacturer

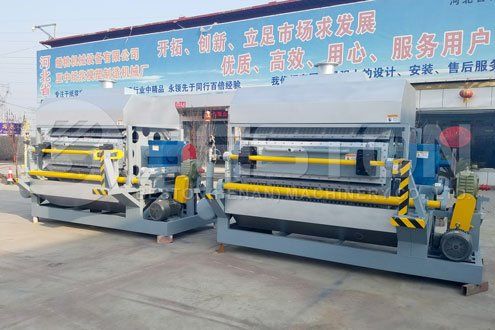

The rotary egg tray making machine uses sustainable packaging materials, as it is crafted from recycled materials which can later be recycled again after they reach the end with their life-span. Together with the extensive applications for your paper egg trays, these appliances have started significantly in popularity over the years. Get the great paper egg tray making machines

from experienced suppliers.

These automatic egg tray making machines provide a procedure that is fully automated. One of many unique characteristics connected with these appliances will be the automated egg-tray dryer. This permits for a way to automatically dry wet, semi-finished egg trays. The rotary egg tray making machine have the capability to produce between 5000 and 7500 pcs paper pulp egg cartons every hour. The normal models for these automated machines range from the BTF-5-8 and the BTF-4-12. There are projects about pulp moulding machine manufacturers in India

.

It is important for investors to make certain that the device they purchase is specialized for producing egg trays which can protect the eggs from elements like:

•Micro-organisms

•Moisture loss

•Deteriorating from extreme temperatures

•Mechanical shock caused from transportation, storage and handling.

The Way The Automatic Egg Tray Machines Work

In relation to buying an egg tray making machine it will become essential to gain an understanding in regards to the component systems. This will likely add the personnel allocation, the covering-area, the capital invests, production time or anything else. Listed here are the 3 systems involved in the rotary egg tray making machine:

1.Pulp System

To begin the process recycled paper including corrugated carton or newsprint is put within the pulper. Here the machine will smash and beat the paper until it reaches a pulp consistency. This pulp will likely get into what is known as a pulp-adjusting tank. It really is from this point how the pulp will be adjusted to your pulp consistency that is certainly ready.

2.The Forming System

Inside the forming-system are forming tools which feature wire mesh and transfer tools. The wet produce is created by using a vacuum system. The wet product which has become formed are transferred on the transfer-tools with the use of a compressed air-effect.

3.Dryer

Dryers in the fully automated paper-egg tray making machines offer 2 types including the one-layer dryer combined with the multi-layer dryer. The wet merchandise is then passed through the dryer tunnel. When the trays get to the other part, these dried products may then be stacked and counted. Deciding on a fuel will be reliant on the conditions, but typically include either natural gas or diesel. The choice of natural gas or diesel is considered the more environmentally friendly choice. Go on BestonTurkey.com/

to get more tips.

These automatic machines may also be called rotary egg-tray making machines as the machine works on rotary running. When selecting more than one of these machines you should make use of a recognized and reputable manufacturer. These firms may give guidance on your specific requirements and definately will send professional engineers so that you can install the machines. The engineer technicians may also give instructions on the way to operate the machinery along with guidance on to have the highest profits within the shortest period of time possible.