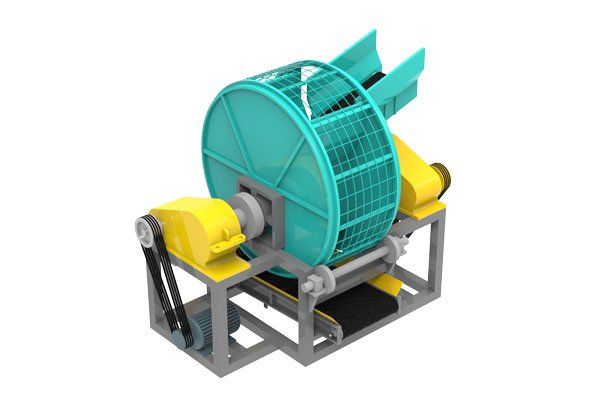

An Overview Of The Tire Shredder Machine

Tyre Shredder for Sale

Tire shredding is one of the most common ways to prepare scrap or waste tires for recycle or disposal. Before tires may be disposed of in landfills, they should be shredded into smaller pieces. The desired size will generally be determined by the region or claim that you stay in. Today a lot of companies now shred tires to recycle tires, tire mulch, or crumb tire, that is then reused for creating surfaces on athletics tracks, roads, playgrounds, plus more. Get the tire shredding equipment for sale

.

This is where a tire shredder machine will come in because it serves a vital purpose. It is important to gain an understanding of methods these machines work, to determine whether one of these simple machines will manage to benefit your small business.

1. Primary Tire Shredders

A primary shredder will be the first portion of the machine that scrap tires proceed through. They are robust shredders that take whole tires and turn them into 2" to 6" rough shreds. These machines typically process around 10 to 30 plenty of tires or rubber in an hour. The primary shredder features either 1 shaft or 2 shafts.

The only-shaft shredders are fantastic to generate uniform pieces. The two-shaft shredder typically produces rougher shreds, nevertheless the overall shredding process is faster. The 2-shaft shredder can also be longer-lasting and a lot more durable.

The principal shredders only involve one step when it comes to tire-shredding because the large pieces created will likely then have to go through a secondary shredder to refine the pieces even further.

2. Granulators, Mills, And Graters

The next thing of your process requires the rough tire shreds experiencing the secondary shredder of a tire shredder machine, which is known as the grater. This method refines the tires into chips to sizes of 1" or smaller. Tires also contain steel wire which is filtered out with the secondary shredders. Or you choose the pyrolysis plant Philippines

to process tyre.

After passing throughout the grater, the mulch left out then experiences the granulator. It is a high-speed processing machine which is used to remove many other materials, for example polyester and nylon. This technique produces the content into crumb rubber. This crumb is produced through extremely fine tire-shredding, and also the "crumbs" are around 3/8" in size.

When finer shredding turns into a requirement, the ultimate step that the tire shredding machine will feature is definitely the milling equipment. The crumb rubber will be placed in a fine grinder, or cracker mill, in which the pieces are further reduced to around 2mm or smaller, which generates a "rubber powder".

Each step associated with processing tires is always to refine the rubber into smaller and smaller pieces. The principal shredder slices the complete tires up into bits of rough chunks of about 2" in proportion. Each machine used from here will reduce how big the rubber a little bit more, in addition to extract every other materials. Nylon, polyester, and steel wire will be removed successfully during a tire-shredding process, which leaves behind pure and clean rubber powder. The key goal of using a tire shredder is usually to either prepare the waste tires to get a landfill or to reuse the materials taken from the method.